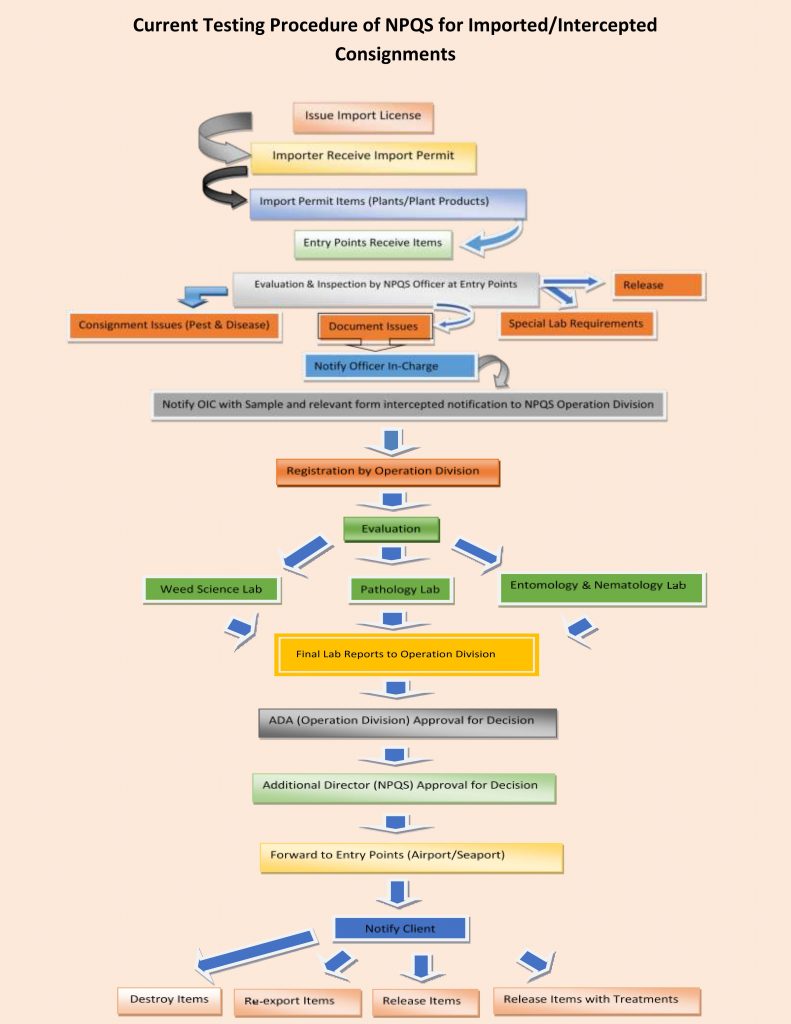

Due to insufficient certifications, inaccurate declarations, non fulfillment of specific entry conditions and visible pest infestation, plant quarantine officers at entry points can not release the consignment. Under such conditions plant quarantine officers of the entry points seek advice/ further testing from the NPQS. Normally plant quarantine officers of the seaport/airport do sampling and send to NPQS / operation division with a form of submission of intercepted materials.

1. Sample submitted from entry ports to the Plant Quarantine Operations Division

2. Registration of intercepted sample with following information.

a. Date received

b. Name and address of the importer

c. Name of the importing country

d. Permit number and date

e. PSC number and date

f. Material and quantity

3. Based on the reason for interception, samples of the material are distributed to relevant technical laboratories for further testing.

4. Printing and distribution of report format to relevant technical laboratories (entomology/pathology/weed science/treatment technology) to submit the test results.